Socket

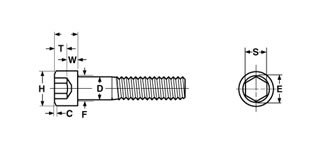

An externally threaded fastener with metric threads, a cylindrical head with a flat chamfered top surface, knurled cylindrical sides, and a hexagonal recess. Generally manufactured in accordance with DIN Standard 912 or ISO Standard 4762

Ideal for precision assembly work with close tolerances and applications needing a well tooled appearance. Supplies greater tensile strength than equivalent sizes of hex cap screws while requiring less surface area or counter-bore since the fastener is internally wrenched.

Properties

| Diameter Range | M16 to M56 dia and length up to 700mm long. |

| Threads Type | MM, BSW, BSF, UNC, UNF and Fine Pitch |

| Material | Stainless Steel, Alloy Steel and also as per customer requirements. |

| Standards | DIN, ISO, IS, BS, ANSI |

| MTRL. GRADE | Stainless Steel – 304, 304L, 316, 316L, 316 Ti, 310, 202… |

| High Tensile | 8.8, 10.9, 12.9, B7, B16 |

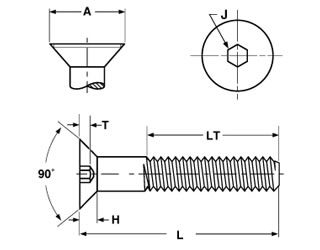

Has a similar design as a metric button head socket cap screw, but has an 90° countersunk flat head. Generally manufactured in accordance with DIN Standard 7991.

Used when a flush mounting, high strength screw is required. Commonly used in tools and dies where moving parts are passed over the fastened area.

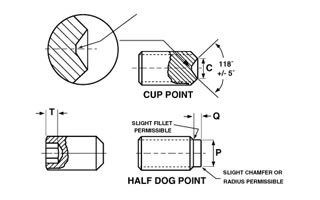

A headless screw threaded the entire length, with a hexagonal drive at one end and a point at the other end (e.g., cup, half dog, oval, flat, and cone).

Used for internal wrenching and where frequent disassembly or adjustment occurs.

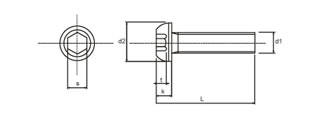

Has a similar thread design as a metric socket head cap screw. However, the dome-shaped head is wider and has a lower profile than a metric socket head cap screw. Generally manufactured in accordance with ISO Standard 7380.

Used when a wider bearing surface or a smoother, more finished appearance is desired. Button head cap screws do not afford the strength of socket head cap screws and are designed for light fastening applications. They are not recommended for critical, high-strength applications.